●

●

●

Products

Products Products

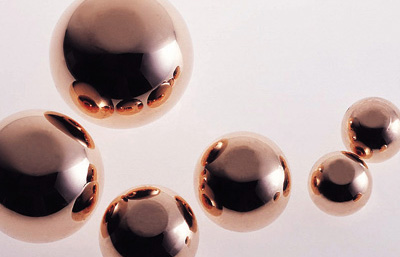

Products Copper Anode

Copper AnodePhotographs of Products |

|

Manufacturing Purposes |

|

|

Copper containing neither oxygen nor reducing agent, which is melted and cast or melted with reducing by charcoal in vacuum. Its oxygen content shall be 0.001%(10ppm) or less. It shows good electrical conductivity, no hydrogen brittleness and excellent machinability.

Adding phosphorus for deoxidization to tough pitch (electrolytic tough pitch, ETP) copper, which is obtained by melting and refining electrolytic copper, makes phosphorus deoxidized copper(DLP or DHP), which is to be transformed, with adequate quantity of phosphorus added, to pyrophosphate copper of which oxygen and residual phosphorus content should be 0.01% or less and 0.040 to 0.065%, respectively.

|

|

|

| Ф55 | 54.0 ~ 56.5 | 800±10 |

| Ф50 | 49.0 ~ 52.0 | 600±6 |

| Ф45 | 43.5 ~ 46.0 | 425±6 |

| Ф38 | 36.5 ~ 39.0 | 256±6 |

| Ф30 | 28.5 ~ 31.0 | 125±5 |

| Ф25 | 23.5 ~ 26.0 | 74±5 |

| Ф11 | 9.5 ~ 13.0 | 7±3 |

|

|

||||||

| KS/JIS | UNIS | Cu | Pb | Fe | Sn | Zn | Others |

| - | C10200 | 99.96↑ | - | - | - | 0.001↓ | O²: 10ppm or less |

| - | C12220 | 99.90↑ | - | 0.040 ~ 0.065 | - | 0.01↓ | P: 450ppm Target |

|

|

|

|

|

|

|

|

| KS/JIS | UNIS | ||||||

| - | - | - | - | - | - | - | - |

|

|

|

| Electrolyte | Acid and alkali in common/cyanide solution | Acid designated/acid copper sulphate |

| Current Density | High: appr. 3A/dm² | Low to medium: appr. 2.2A/dm² |

| Polishing | Not polished | Polished |

| Plating Method | Horizontal | Vertical |

| Use | Plating of high performance PCB and electroless plating | Plating of high performance PCB and undercoating of general products |

| Remarks | Favorable to precise plating | Favorable to mass production |